Custom Inflatable Seal for a Robotic Thermospray Booth Door

We provided a durable, heat-resistant inflatable seal for a 180-degree rotating door in a robotic thermospray booth.

Industry

Welding, Manufacturing

Application

Robotic Thermospray Booth

Industry

G-12, EPDM

Industry

United States

Industry Background

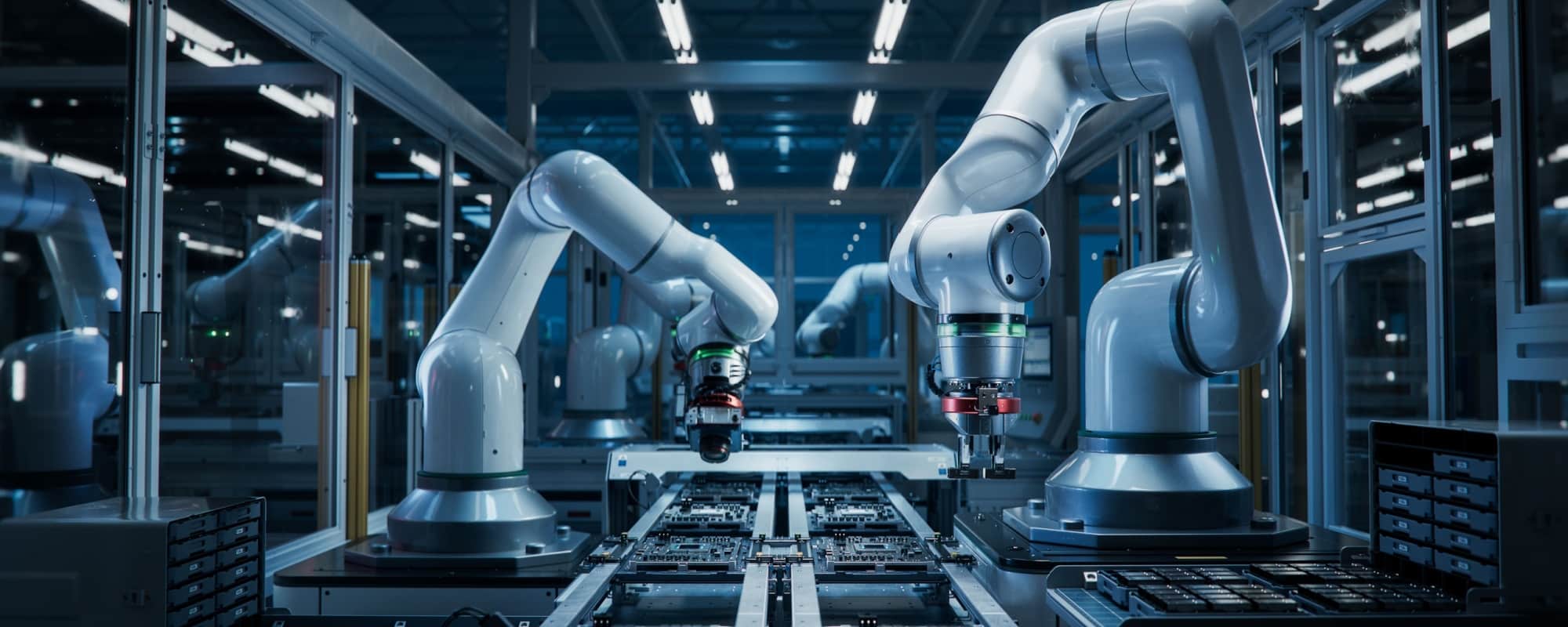

The welding and manufacturing industry demands highly controlled environments to ensure precision, safety, and efficiency. Robotic thermospray booths, which involve superheating metallic media and applying it to components such as gear shafts, require specialized environmental sealing solutions. These booths generate significant heat and airborne metal particles, necessitating effective containment to protect both equipment and personnel.

Project Details

Client: Arzell, Inc., a leader in equipment manufactured for thermal spray and general automation markets

Requirement: To provide a durable, heat-resistant inflatable seal for a 180-degree rotating door in a robotic thermospray booth, ensuring environmental containment and worker safety.

The Challenge

The client required an effective seal for a large (6x8 feet) rotating door that could pivot in a "C" shape. The booth's environment presented several challenges:

- Extreme heat and airborne sparks from the welding and thermospray process

- Containment of hazardous gases and metallic dust

- A seal that would not interfere with the door's rotational function

- A quick, easy installation solution that minimizes downtime

The Solution

Seal Master Corporation designed a specialized inflatable seal using EPDM, the most suitable material for this high-heat and particulate-heavy environment. The G-12 cross-section was selected for its effectiveness in sealing off airborne contaminants while allowing the door to pivot freely without excessive friction. Key factors contributing to the solution included:

- Material Choice: EPDM was chosen for its high heat resistance and ability to block dust, metal particles, and hazardous gases.

- Design Consideration: A strip seal was used rather than a continuous seal, ensuring both ends were properly sealed while maintaining door mobility.

- Ease of Installation: The snap-in base design allowed for a plug-and-play installation, requiring minimal effort from the client’s team.

- Efficiency in Response: Our team quickly assessed the available space and designed a fitting solution within a short turnaround time.

The Results

The inflatable seal effectively controls environmental factors within the robotic thermospray booth, preventing metal particles and harmful gases from escaping while withstanding the high-temperature environment. The success of this solution led the client to place additional orders for seals tailored to other chamber sizes, reinforcing their trust in Seal Master Corporation’s expertise.

Our ability to provide a fast, effective, and repeatable solution showcases our commitment to supporting manufacturers with innovative and reliable sealing technologies.

Arzell, Inc. specializes in the design and manufacture of advanced machinery for the thermal spray industry, where high heat and velocity are used to bond engineered metals to cost-effective substrates. This process is inherently loud, dirty, and hazardous, which makes operator safety a top priority. To mitigate these risks, Arzell integrates industrial robots within protective enclosures, featuring custom-designed indexing turntables. These turntables allow operators to interact with parts outside the enclosure while the thermal spray process is conducted safely inside.

Seal Master plays a crucial role in our operations by supplying the inflatable seals that encircle the perimeter of our indexing turntables. These seals provide critical protection by safeguarding operators from the dangerous heat, noise, airborne pollutants, and potential arc flashes generated during the process. Their team is consistently responsive and supportive, ensuring that we have the best solutions for our needs. Seal Master’s fabric-reinforced inflatable seals are as durable and reliable as the machinery we build, contributing to both enhanced safety and improved process efficiency for customers.

—Brad Margiolos | Mechanical Design Manager at Arzell, Inc.

Need help with your project?

If you’re working on a project of your own and struggling to find the right solution, our engineering team can work with you to solve any problem.